Header

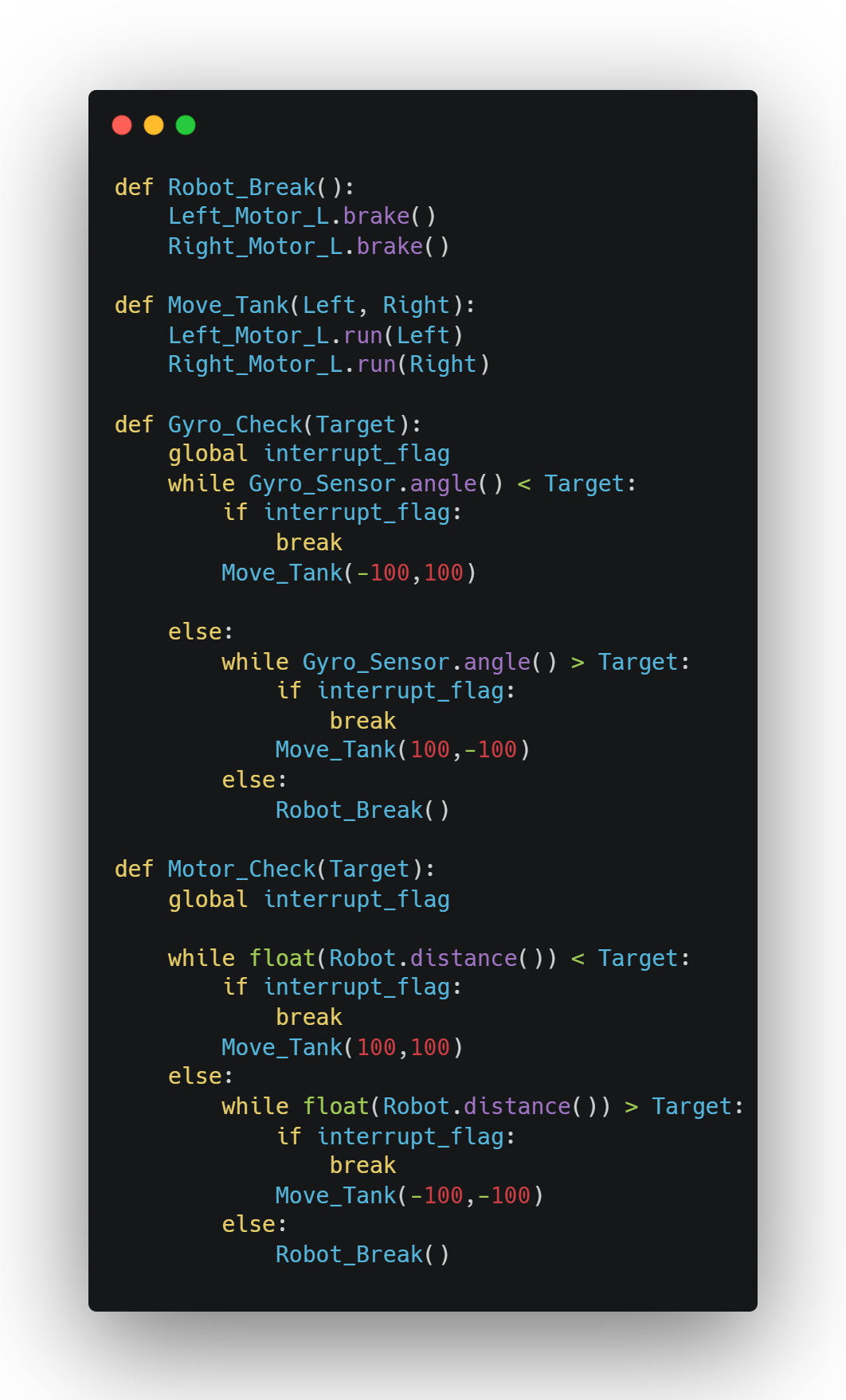

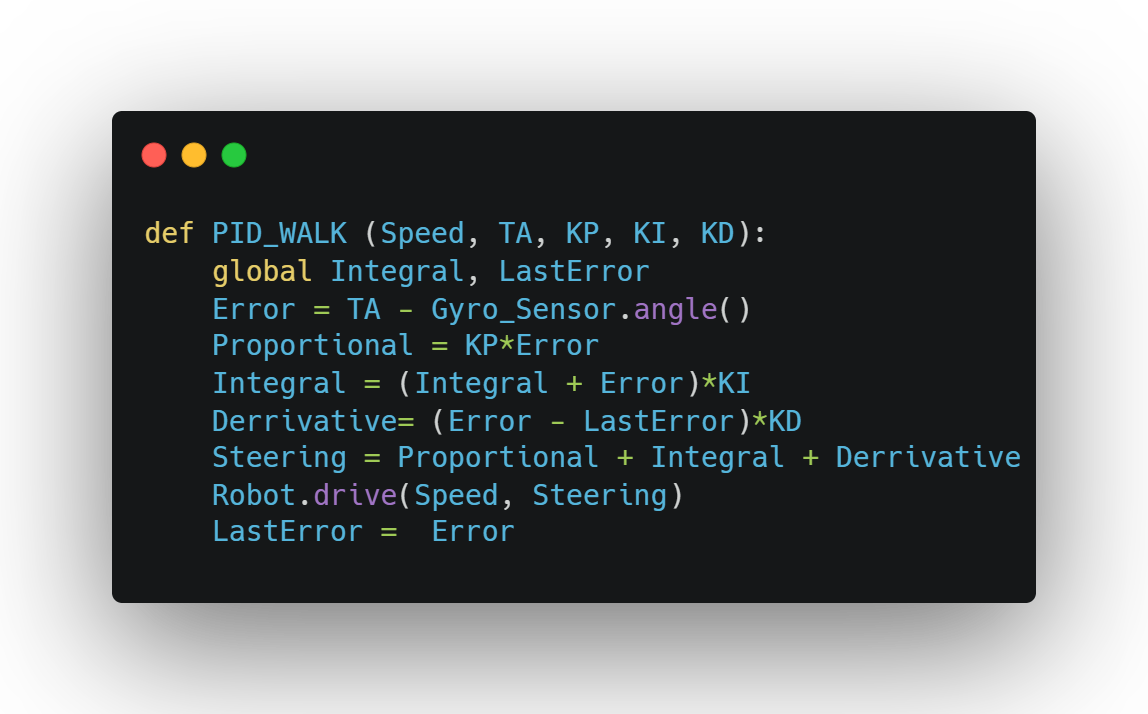

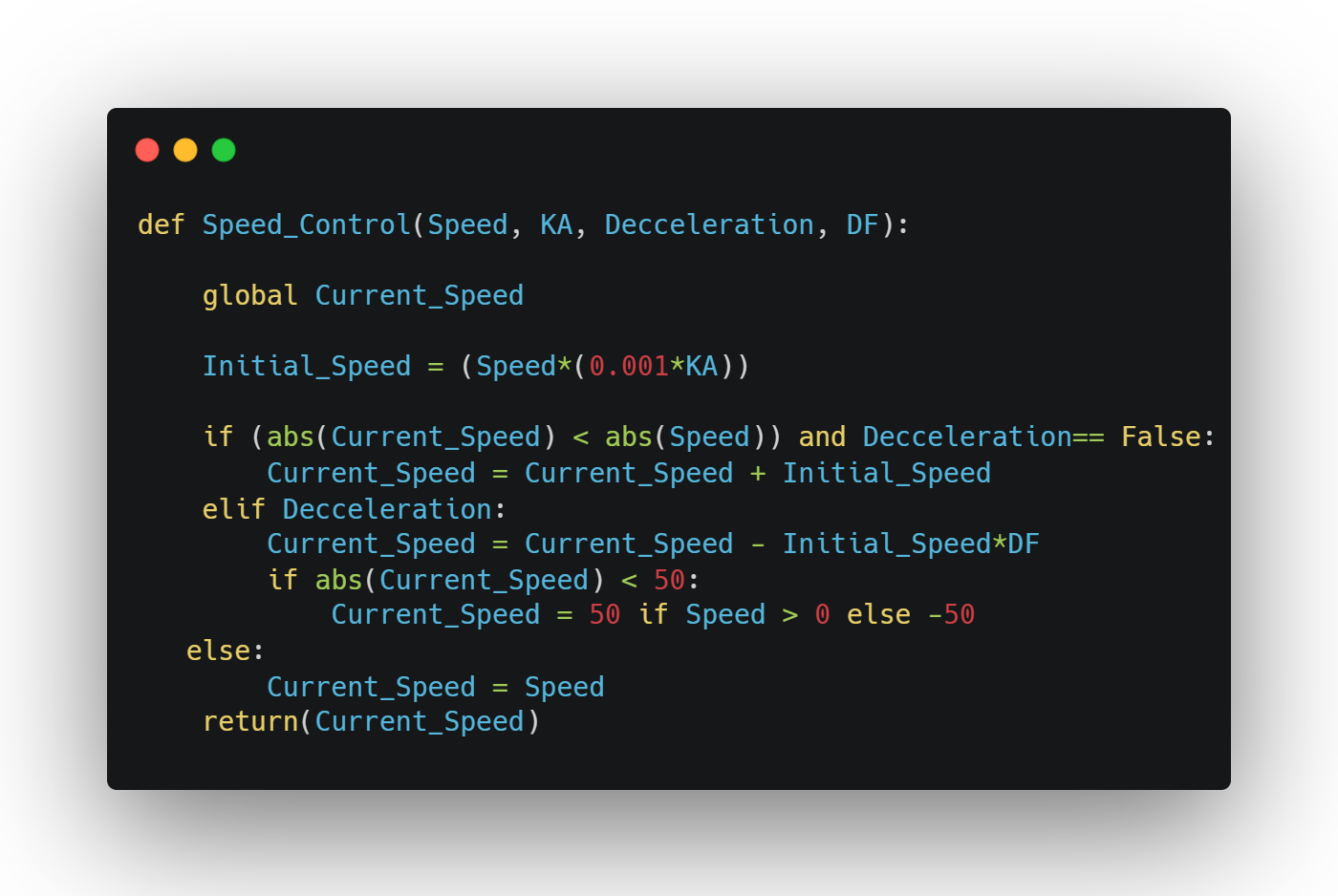

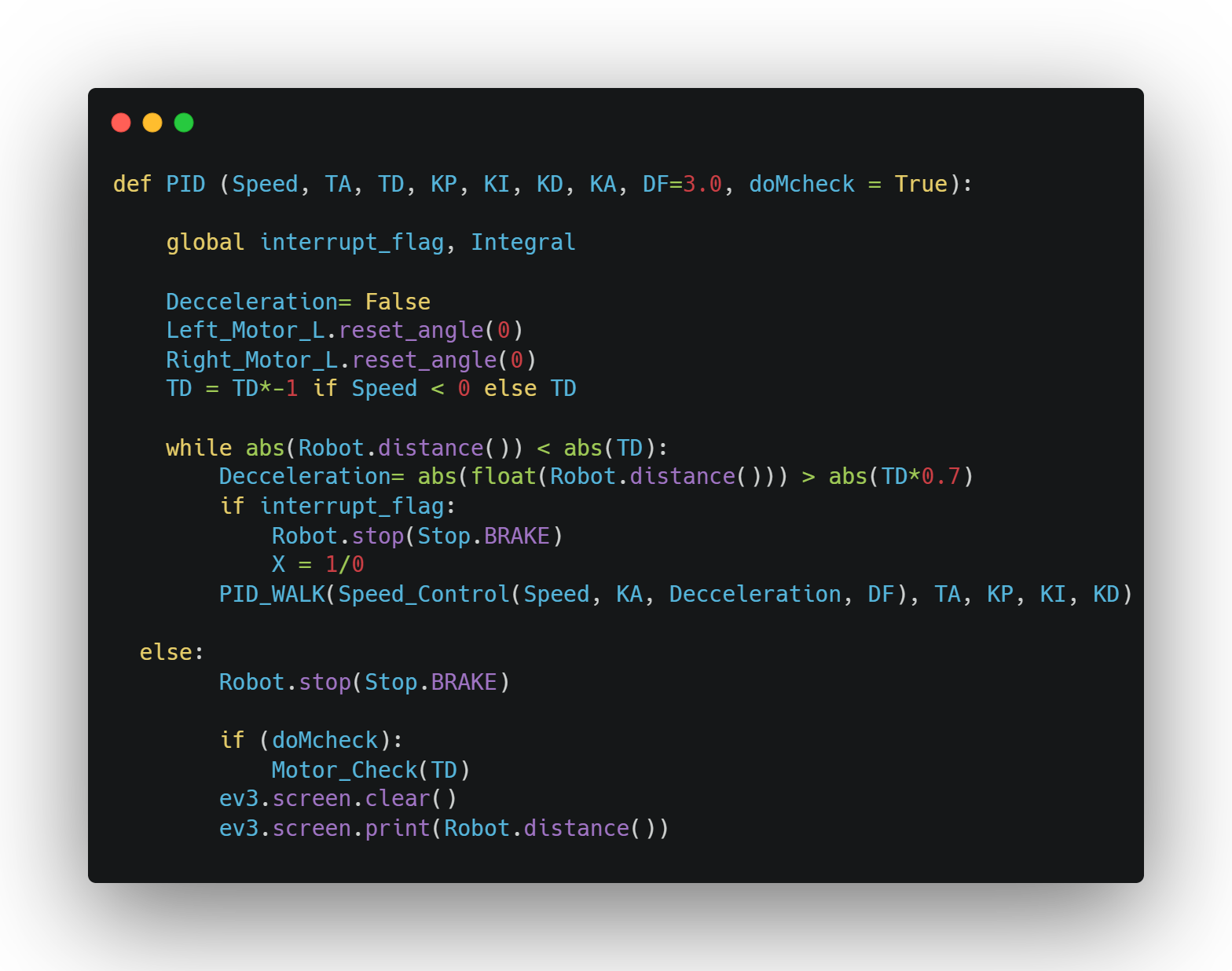

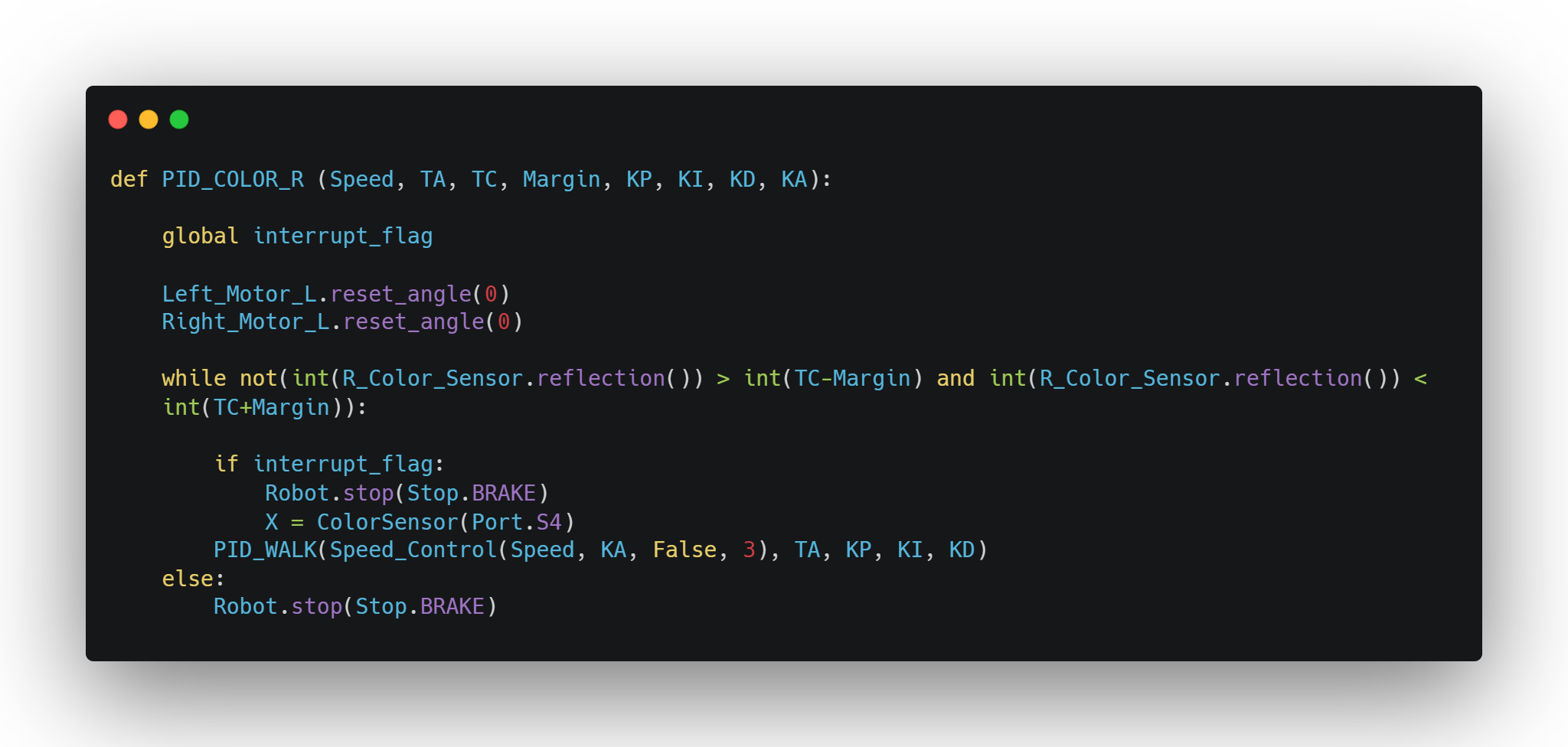

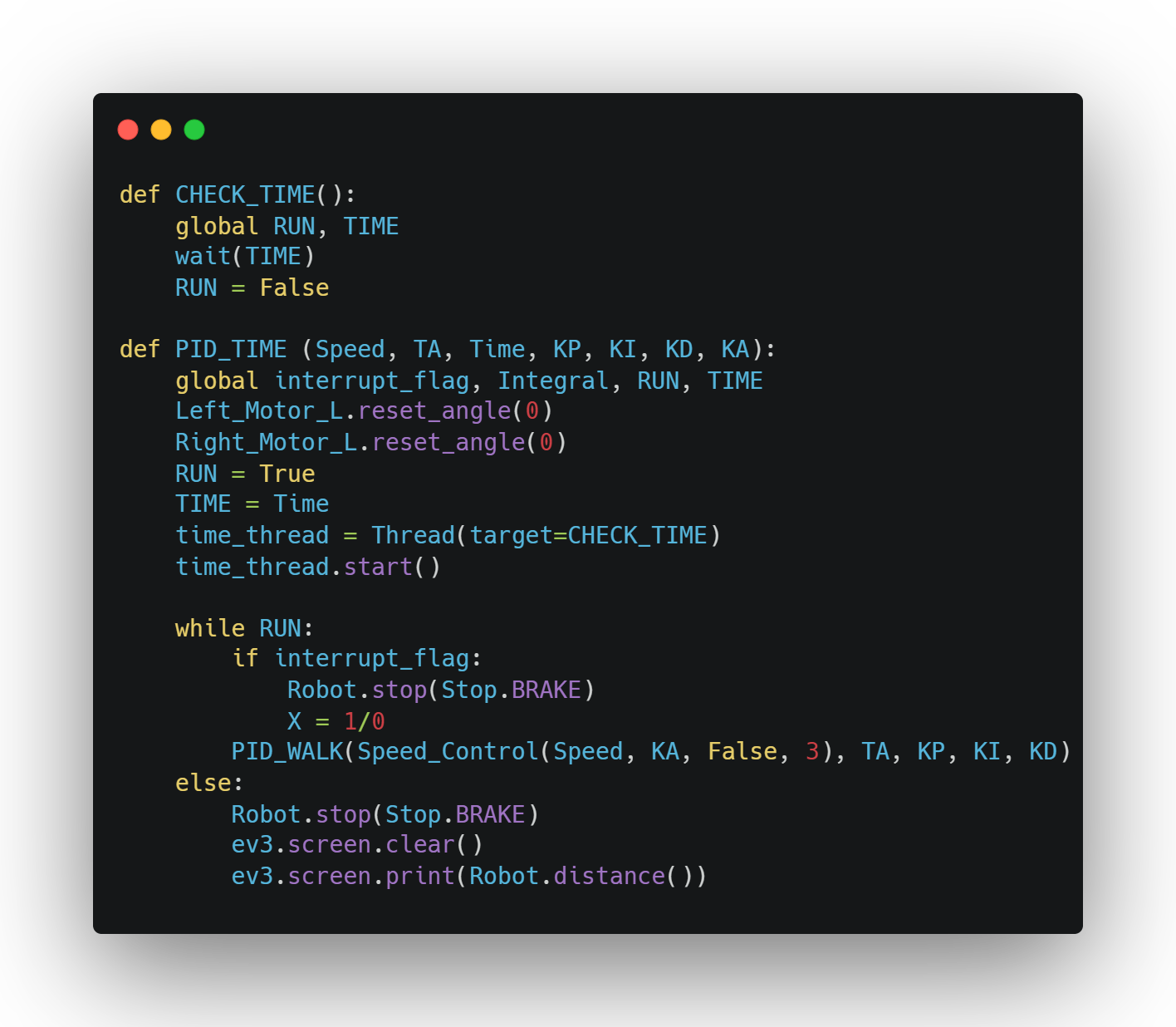

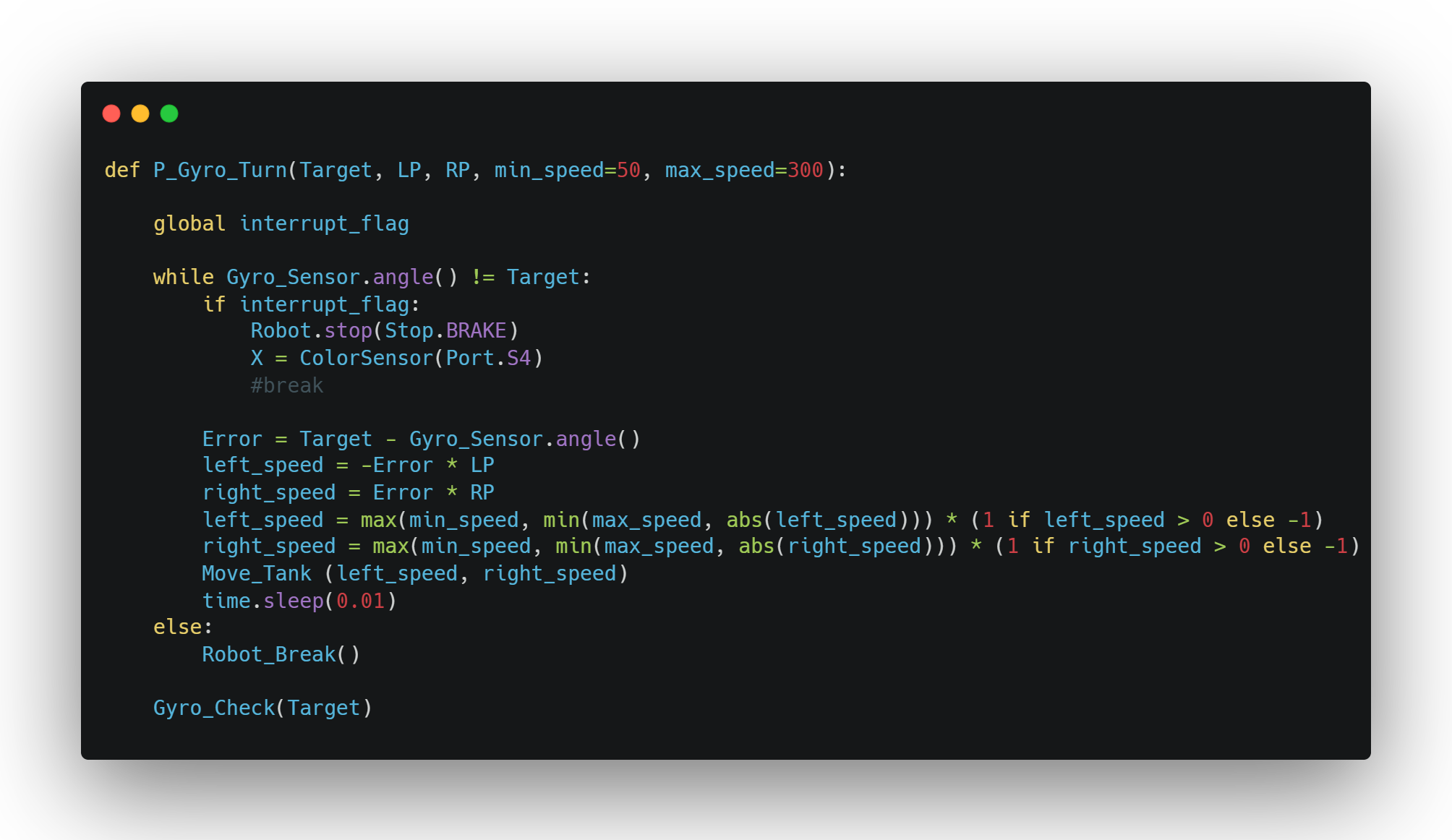

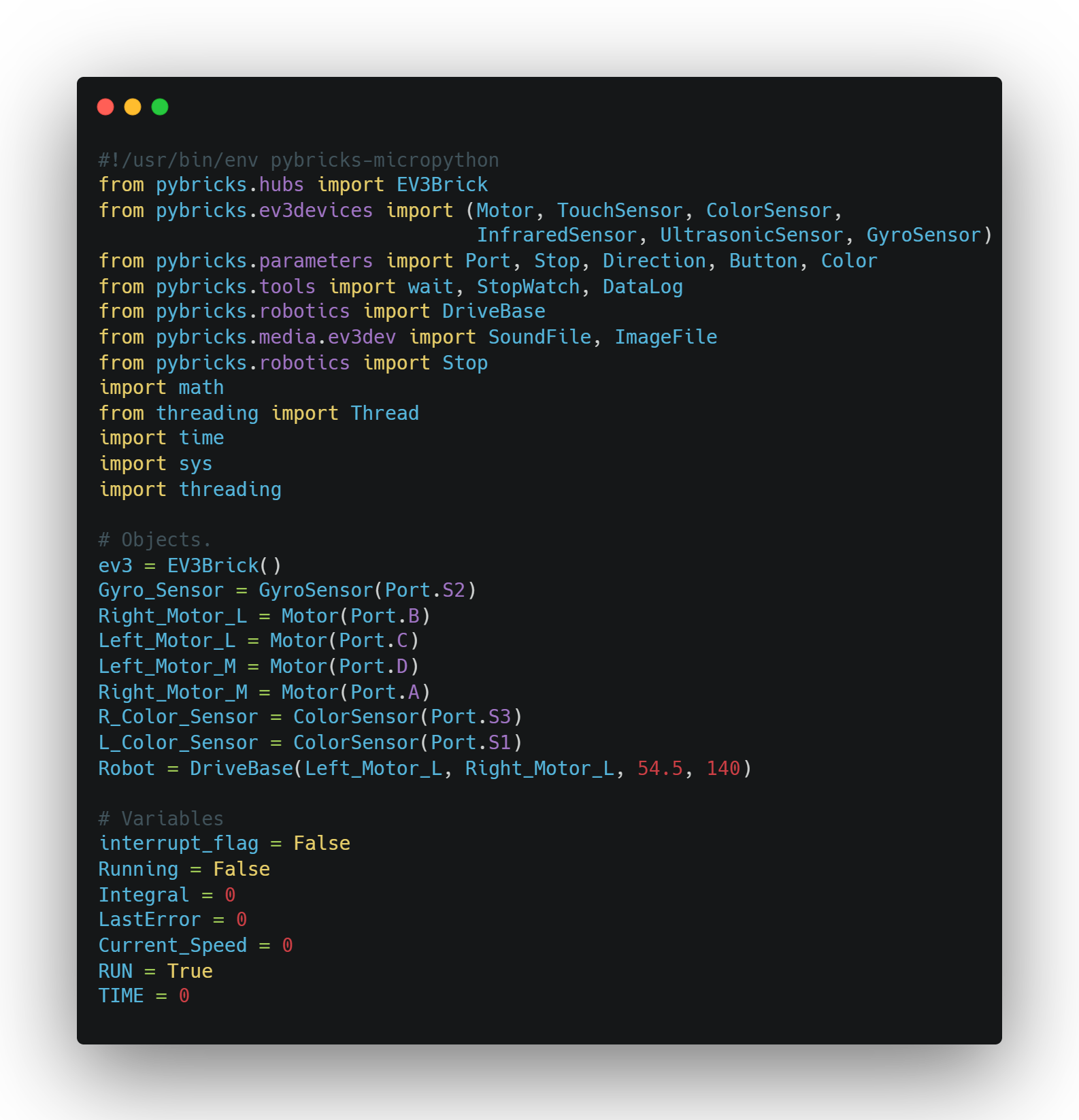

This MicroPython script is designed to control a LEGO EV3 robot using the Pybricks library. It begins by importing essential modules for hardware control, such as motors, sensors (gyro and color), and system tools like math and threading. The EV3 brick and multiple motors are initialized, likely with two dedicated to movement (Left_Motor_L and Right_Motor_L) and two possibly for attachments or mechanisms (Left_Motor_M and Right_Motor_M). Two color sensors are set up for detecting colors or following lines, while a gyro sensor is used to measure rotation or orientation. The robot’s drive base is configured with the wheel diameter and axle track for precise movement. Additionally, variables related to robot state and motion control, such as interrupt_flag, Running, and PID-related terms (Integral, LastError, Current_Speed), are declared—indicating that the robot may use PID control for navigation or line following. The script sets up the foundation for a responsive and sensor-driven robotic system, with support for multi-threading to handle complex tasks.